Rating of the best dry ovens for manicure for 2020

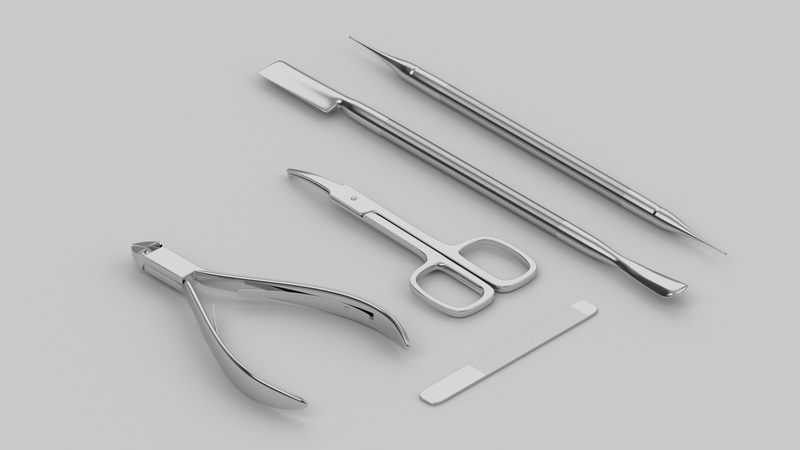

The market of services in the field of beauty provides a wide range of services of any specialist. Finding a manicure and pedicure master is not an easy task. Since, if we visit the beautician several times a year, then beautiful and well-groomed nails require more frequent visits to the salon. Now there are quite a few people providing these services. Someone works in the salon, and someone leads the reception at home. When choosing a nail master, pay attention not only to his skill, but also the cleanliness of the cabinet and the processing of tools. The further condition of your hands depends on proper sterilization and disinfection. And the master, in turn, will need a special drying cabinet for manicure.

Tool processing rules

To prevent the spread of viral and infectious diseases from the client to the master or other clients, manicure should be carried out only with sterile instruments. For this, it is necessary to carry out disinfection and sterilization in three stages.

For complete purity, it is necessary to carry out all three stages, and it is impossible to change their sequence and it is recommended to strictly follow all the rules.

The first step is to disinfect the instruments. This step is necessary to remove viruses, fungi and infections from the surface of the instruments. To do this, it is necessary to fill the instruments with a disinfectant. Typically, these products are available in the form of concentrated solutions. For their use it is necessary to dilute them with water. It would be more correct to say, add a certain small amount to the water. Each concentrate has its own percentage, and from this you need to calculate the volume of water. Usually, such a solution is prepared in advance. After completing work with the client, the tools in working form are laid out in the solution. The disinfection time is indicated by the manufacturer. It usually takes about 30 minutes.

After the completion of disinfection, you should proceed to the second stage, which consists in cleaning the instruments before sterilization. At this stage, all parts should be cleaned from the remnants of the clients' skin, traces of blood, and possibly the remnants of the disinfectant. If you skip this stage, then these biological particles will only stick more strongly during heat treatment, which not only makes the instrument not sterile, but can also spoil its working functions. This stage is a mechanical cleaning, which is usually carried out under running water, at which time it is necessary to process every detail with a brush. After that, the instruments must be allowed to dry completely and only then proceed to the last stage of processing.

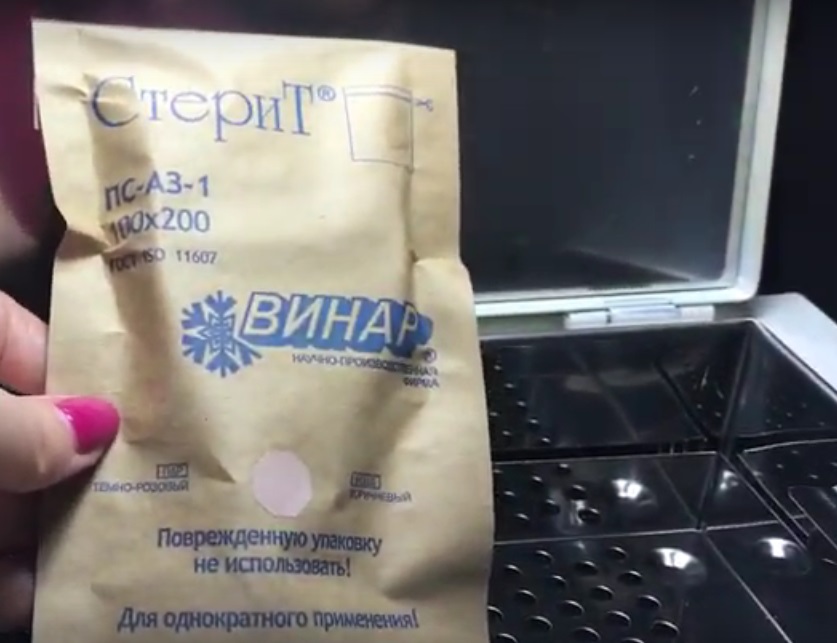

So, the instruments are completely dry, now you can proceed to the final stage - sterilization. It is necessary to remove the spores of certain microbes, which are not destroyed in the first stage using a disinfectant.Usually, sterilization in manicure rooms is carried out using a dry heat apparatus. Before starting the step, make sure that all parts are completely dry. After that, the instruments must be placed in special bags for sterilization. The filling of the bags should be 2/3 of the volume of the bag. The bag must be sealed before sterilization. The duration of the process depends on the set temperature. At the end of the sterilization time, the instruments must cool in the cabinet itself, after which they can be removed.

What is a dry oven

A dry oven, or as it is also called a dry heat or heat sterilizer, is used in beauty salons and medical institutions to process instruments in order to get rid of germs and bacteria. The principle of its operation is based on the processing of products with dry air at a temperature of 180-200 degrees. It gained popularity due to its low cost, unlike autoclaves.

The thermostatic sterilizer consists of a chamber where the process itself is carried out, there is also a heating element inside. There are grates inside the chamber, where bags with products that need sterilization are laid out. Also, this equipment has a special panel where you can adjust the temperature and processing time of products. Thanks to special ventilation, the cabinet inside and all the tools in it are quickly heated.

If you process products at a temperature of 160 degrees, then the process should last at least two hours, at a temperature of 180 degrees one hour will be enough, and for the process to take half an hour, then the temperature should be 200 degrees.

Nuances in working with a dry oven

Unlike an autoclave, the principle of which is based on the temperature of humid air, this sterilizer works with dry air. Therefore, it processes instruments at higher temperatures than an autoclave. Before starting work, you must take this feature into account and be careful about the material of the sterilized product, so that during the processing it does not lose its shape and presentation. But for metal products, this method will undoubtedly be an advantage, since when processing with steam, the product will corrode. Also, unlike autoclaves, a thermostatic sterilizer has a lower cost and consumes less energy, which reduces costs during operation.

But besides the advantages, there are also small disadvantages. For example, the processing process takes longer, especially if you set the minimum allowable temperature. Such processing can slow down the workflow. It is also necessary to follow the loading rules, the loaded products must be evenly distributed over the sterilizer. This is necessary for uniform air circulation, which will ensure that all bacteria, fungi and viruses have been destroyed.

How to choose a dry oven

Before you start looking at specific models, pay attention to your customer turnover and how much tools you use. Now let's take a closer look at the criteria to which you should pay attention.

First of all, dry heat are distinguished by their capacity, i.e. volume. If you work from home, or you have a small office with an average turnover of clients, then a small volume will be enough for you. Beauty salons that have several manicure and pedicure masters need a more voluminous apparatus. This will not slow down the work of the masters, since a large number of products can be loaded at once.

Pay attention to the performance of the sterilizer. The heating rate will depend on this indicator. The faster it heats up, the faster your tools will be processed and ready to go.

Also, many models have additional functions. For example, cooling after processing or communication with a computer to control the frequency of processing. Not all of them are actually necessary, but the cost of such devices will exceed the price of a conventional oven.

In addition, pay attention to temperature conditions.Powerful models have higher temperature gradations. The higher the processing temperature, the less time the process will take.

The best dry ovens for manicure

Sanitizing Box CH-360T

This Chinese-made thermo sterilizer is designed to process not only manicure devices, but also medical devices.

The inner case of "CH-360T" is made of stainless steel. A removable container is also available, which can be used both for sterilization and for transferring and storing products. For ease of use, there are two indication lamps. One of them shows the heating of the device to the set temperature, the second refers to the timer. The timer allows you to set the time from 0 minutes to 1 hour. When finished, a beep will sound. This dry heat model works in the temperature range from 0 to 220 degrees. The required temperature should be selected depending on the material of the processed devices.

The volume of "CH-360T" is 1.8 liters, weight - 3.8 kg. Product size is 31 * 14 * 18 cm. "CH-360T" has a power of 300 watts.

The average cost is 3000 rubles.

- Small size;

- There is a timer;

- Temperature indication lamp;

- Suitable for home use;

- Affordable cost.

- The timer is only for 60 minutes;

- Not suitable for use in large beauty salons.

Sanitizing Box SM-360B

"Sanitizing Box SM-360B" is widely used in cosmetology and manicure rooms, as well as in medical institutions. It is suitable for processing metal and glass fixtures. It can be used to disinfect instruments from bacteria, microbes and fungi for 99.9%.

The inner chamber and handy tray are made of stainless steel. For added convenience, the kit includes a removable container and accessories that can be used to remove the processed products and the tray from the chamber.

Sanitizing Box SM-360B is easy to use. To control the time, there is a special timer that can be set up to 2 hours of operation. This thermal sterilizer operates in a temperature range of 0 to 200 degrees. It also has a display on the control panel that displays the remaining time and temperature of the device.

The internal volume of "Sanitizing Box SM-360B" is 2 liters. The dimensions of the device are 31 * 14 * 18 cm, while the chamber size is 25 * 12 * 6 cm, and the tray size is 24.3 * 11.3 * 2.7 cm.The product weight is 4.2 kg. The power is 300 watts.

The average cost is 3800 rubles.

- Compact size;

- Display showing temperature and remaining running time;

- Timer from 0 to 120 minutes;

- Tools for removing the tray and tools.

- Not.

Sanitizing Box KH-360B

Sanitizing Box KH-360B is a sterilizer that is widely used for disinfection of manicure, pedicure and cosmetic equipment. It has a stylish design, thanks to which it will look beneficial both in beauty salons and at home. A distinctive feature of this model is the LCD display, with the help of which it is easy to set the necessary processing parameters.

The outer casing is made of metal and covered with a white paint that is resistant to disinfecting. The inner chamber is made of stainless steel, the container for storing and handling accessories is also made of stainless steel. The Sanitizing Box KH-360B is suitable for sterilizing 3 sets of manicure instruments. Also, this model is equipped with special rings for removing the tray.

The possible processing temperature for inventory varies from 50 to 220 degrees. There is a timer that can be set up to 1 hour of operation. At the end of the sterilization process, an audible signal will sound.

The chamber volume is 1.8 liters. The size of "Sanitizing Box KH-360B" is 31 * 14 * 14 cm, while the chamber size is 25 * 12 * 6 cm. The power of the device is 300 watts.

The average cost is 4000 rubles.

- Electronic scoreboard showing the time until the end of the process;

- Temperature sensor showing the current temperature of the device;

- Convenient management;

- Stylish design;

- Compact size;

- The ability to simultaneously sterilize up to 3 kraft bags.

- Not.

Sanitizing Box WX-12C

This model of dry oven from the Chinese brand "Sanitizing Box" is intended for professional use. Distinctive features of this thermal sterilizer are high power, large volume of the inner chamber and the ability to maintain temperatures up to 250 degrees. But the manufacturer does not recommend processing manicure or pedicure devices at the maximum temperature, since this may negatively affect the quality of the products in the future.

The inner chamber is made of stainless steel, and there is also a container designed for heat treatment or storage of inventory. It should be noted that the outer part of the "Sanitizing Box WX-12C" has a protective coating of white paint, which will not change color in the future, and is also resistant to minor mechanical stress and disinfection.

For the convenience of controlling the sterilization time there is a timer, the maximum possible setting time is 30 minutes. A beep will sound when finished. The inner chamber has an infrared lamp, which heats the device. There is also a temperature sensor, which can be controlled using an indication lamp.

The volume of the inner chamber is 7 liters. The size of "Sanitizing Box WX-12C" is 22.5 * 21 * 32.5 cm, while the chamber size is 19.5 * 20 * 18 cm. The weight of the device is 4 kg. The power is 1000 W.

The average cost is 4800 rubles.

- High power;

- Chamber volume - 7 liters;

- An infrared lamp controls the heating of the device;

- Suitable for salon use.

- The maximum timer setting is 30 minutes.

Dry oven RuNail

This model of the thermal sterilizer from the RuNail company is suitable for disinfection of manicure and pedicure instruments. The inner chamber of the dry heat chamber is made of stainless steel, in addition, a special tray is included in the kit for storing and disinfecting devices. For the convenience of time control, there is a timer. The maximum time set by the device is 120 minutes. Supported temperature conditions from 0 to 200 degrees. There are indicator lights, with the help of which the set temperature is controlled. Remove the inner protective film before starting work.

The volume of the inner chamber is 1.8 liters. The cabinet size is 31 * 18 * 16 cm, while the chamber size is 25 * 12 * 6 cm. The weight of the dry heat cabinet is 4.2 kg.

The average cost is 5200 rubles.

- Timer for 120 minutes;

- Small size;

- There are indication lights for temperature control.

- Only holds 1 craft pack.

Conclusion

Wherever you are receiving clients at home or in a beauty salon, first of all, you need to take care of safety. The client, seeing that all instruments are sterile, will definitely return to you again. The correct handling of fixtures is important not only for the customer, but also for the craftsman. Moreover, not every client can suspect that they have any diseases that can be transmitted through blood or skin residues on the instrument.

new entries

Categories

Useful

Popular articles

-

Top rating of the best and inexpensive scooters up to 50 cubic meters in 2020

Views: 97661 -

Rating of the best materials for noise insulation for an apartment in 2020

Views: 95022 -

Rating of cheap analogues of expensive medicines for flu and colds for 2020

Views: 91751 -

The best men's running shoes in 2020

Views: 87681 -

Top ranking of the best smartwatches 2020 - price-quality

Views: 85091 -

Best Complex Vitamins in 2020

Views: 84801 -

The best dye for gray hair - 2020 top ranking

Views: 82406 -

Rating of the best wood paints for interior use in 2020

Views: 77202 -

Ranking of the best action cameras from China in 2020

Views: 75269 -

Rating of the best spinning reels in 2020

Views: 74827 -

The most effective calcium supplements for adults and children in 2020

Views: 72463 -

Top rating of the best means for male potency in 2020 with a description

Views: 68296