Rating of the best float switches for 2020

The main purpose of the float switch is to ensure the correct automatic regulation and operation of electric pumps in various systems. Practical, reliable and convenient switches are guaranteed to be used in drains and sewerage systems, drainage systems and water supply systems, where they are assigned the role of not only a monitoring device, but also where they simultaneously perform the functions of a water level sensor, and also protect processing equipment from idle operation at " dry running ".

Competently integrated into the overall system, this device will permanently monitor the functioning of all communication elements and turn on / off the pump in time when the set (or permissible) level of water (other liquid) changes in the system nodes. Usually, the described device is placed in containers, tanks, reservoirs, and in wells.

Design features and functionality of the unit

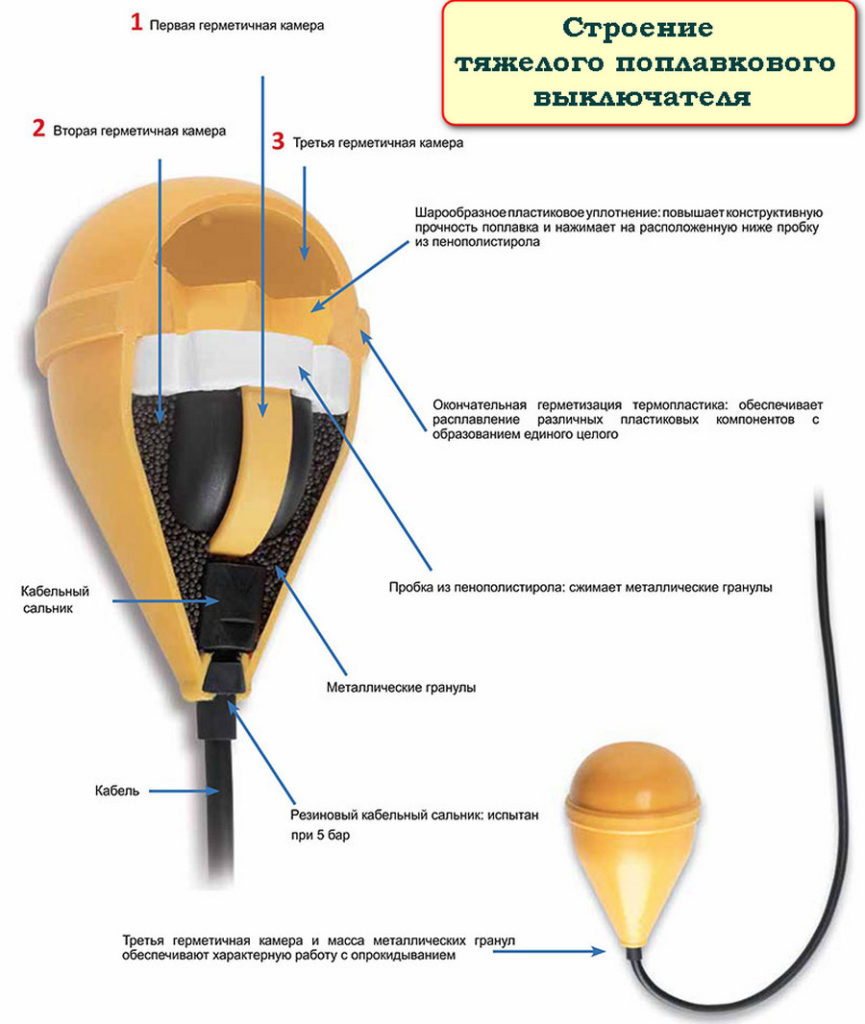

By itself, the design of the float switch is quite elementary. A functional electrical switch is located inside the housing, made of high-strength, heat-resistant plastic. Nearby is a lever for moving the contacts in the switch and a steel ball, which is responsible for the position of the lever element during the change of position of the float itself.

Devices of this type belong to a number of universal options for household / industrial devices, in view of the fact that they work equally correctly both in the event of an empty storage tank and when it is overfilled.

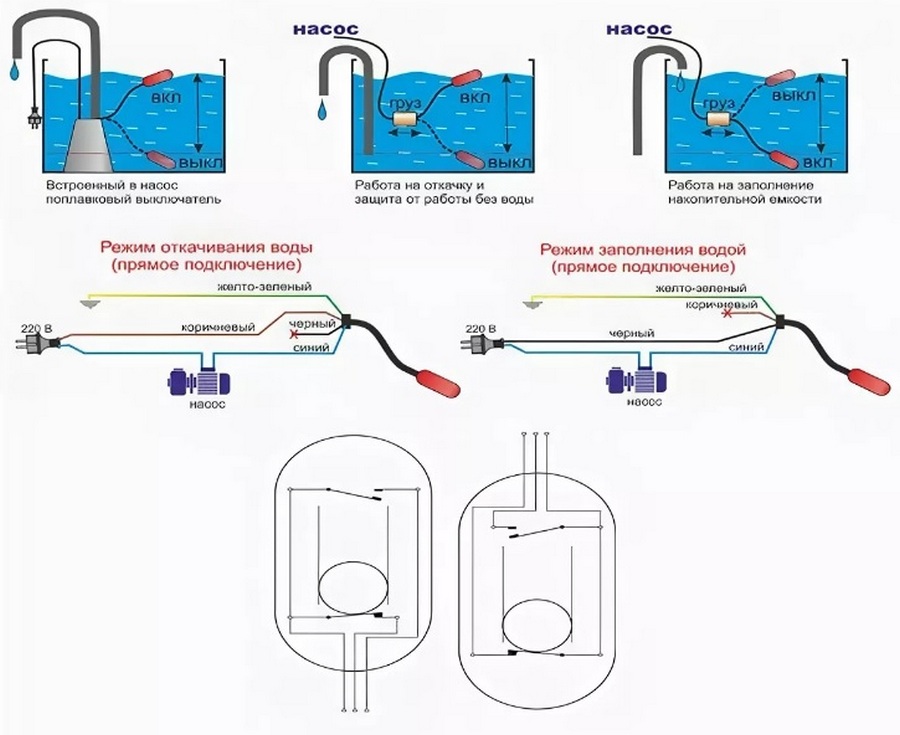

A cable extends from the switch assembly, usually consisting of three wires - black, brown, and blue. Black is common, blue is from the normal open contact of the switch, and brown is from the normal closed.

There are also special requirements for the conductive wire and the housing itself. The first must necessarily have an increased moisture resistance limit, and the second must be completely sealed and impervious to water.

The outlet of the device is additionally secured with a high-strength seal and is equipped with a practical device that neutralizes mechanical stress in the wire.

In turn, the insulated part of the cable gland must be filled with polymer resin, which will exclude the ingress of moisture (or any other liquid) inside and ensure the normal operation of the equipment as a whole.

As a rule, both the case and the sheath of the wire have a high level of strength and heat resistance. Thanks to these properties, they are almost invulnerable to the effects of external elements of an aggressive environment, such as fecal liquid mass, fruit and uric acid, gasoline, as well as liquid oils, etc.

Inside, the space of the float-switch body is filled with air, therefore, the device constantly strives to float and take the highest possible position in relation to the bottom of the tank. If the level of the liquid in the container falls, then the float, accordingly, sinks closer to the bottom.

The length of the wire that is required to move the mechanism is a parameter that controls the spread between the lower and upper position of the float switch. The starting point, relative to which the movement will be carried out, is given by the sinker moving along the switch cable.

The body of the device usually has a non-porous and smooth surface. Fragments of human waste do not stick to it and dirt particles trapped in the sewage channels do not stick. At the same time, paper, grains of sand, and other solid objects simply slide off the unit, in no way affecting its functionality, efficiency and buoyancy.

It should be noted that float switches are extremely functional in themselves and can be adapted to a wide range of tasks. Just a few modules, correctly assembled into a single system in one container, are able to provide:

- Full functioning of the main pump of the entire communication network;

- Effective operation of the auxiliary (auxiliary) pump;

- Fixation of a sharp drop in the level of liquid in the tank, acting as both an emergency controller and an overflow indicator sensor.

All this will noticeably reduce the load on the working equipment and protect the pumping system as a whole from premature wear, transition to dry running and other technical problems and potential malfunctions.

Classification of existing devices

Modern models of float switches are conventionally divided into two types: light and heavy. The first ones are used in pumping complexes that carry out drainage or supply running clean water to the population for domestic purposes. The latter are used in the management of fecal pumping equipment and drainage systems.

IMPORTANT! The purchase of a float switch should be clearly based on future tasks for its use. Lightweight models attract buyers with a low price, but they are adapted to function only in clean water !!!

Heavy units are considered more versatile - they work equally well in clean and polluted environments, but their use in running water is impractical because of their high cost.

Functioning of float switches in various systems

The scope of the considered device is extremely wide. It is effectively used in standard water supply systems, where it quickly controls the emptying / filling of the storage tank, prevents the equipment from idling, thereby extending its service life.

Functioning of a float switch in water supply complexes

The device, placed in the tank, floats to the surface when the tank is filled with water to the permissible (set) limit, and at the same time turns off the working pump, thus preventing liquid overflow.In the case when the liquid level falls, the float drops again to the required level, at which the pump is turned on to fill the container with water. In both cases, having reached the upper or lower limits, the float signals this to the automatic water supply station. Depending on its device, this fact can be recorded in the memory of the operator panel or the signal will pass directly to the central dispatching console.

The filling / emptying process itself looks like this: when a certain level is reached and a corresponding signal from the float device is given, an automated servo is activated, which will open (for filling) or close (when overflowing) the valve or valve responsible for the liquid supply.

Contact with sewerage and drainage

For sewage, drainage and sewage pumps, only heavy type float switches must be used. This is necessary because liquids with a higher density than running water pass through these pumps. In general, the principle of operation of the device is the same as for water supply systems, except that one switch can be connected to two pumps. With a similar scheme, the pumps will work in turn, or they will each perform their own function - one will pump the accumulated liquid when filling the tank, and the second will supply liquid to the tank from an external system.

However, today Rosvodokanal specialists try not to use this scheme and prefer to use its own float switch for each pump. This is due to the fact that sometimes differences in volumes and rates of inflow / emptying of the tank are possible, which leads to a distortion of the correct operation of the device.

Some features of device mounting

It is possible to correctly mount the float switch in several ways. However, first of all, you need to make sure that the current directed to the consumption of the pump is less than the maximum required and specified in the operating instructions for the float.

Standard Single Module Installation

The fastest, easiest and most not laborious way is to install the float in the tank using a waterproof wire and a special weight, which are usually included in the set upon purchase.

The installation procedure is as follows:

- A load is strung onto the cable rope. Then, experimentally, the length of the arm is established, at which there is a free movement of the float device;

- After measuring, the position of the load is fixed on the cable using a special practical clothespin;

- Then the cable is attached to the outer wall of the tank using special fasteners;

- Upon completion of the previous steps, the float itself is connected to the pumping system. Here you must follow the clear instructions in the equipment documentation.

At the end of the implementation of all the necessary procedures, the equipment must pass a performance test without fail. For these purposes, the pump is started in normal mode for 2-3 hours, while it is continuously monitored by the operator. If no failures occurred during the testing period, the liquid is pumped in normal mode, this means that the installation was performed correctly and in compliance with all instructions and recommendations.

Installation procedure for two or more modules

In the case when the design and estimate documentation requires the installation of several float devices, it makes sense to apply the rod mounting method. Any fragment of a strong plastic tube is perfect for the role of a fastener-rod. It is firmly and clearly fixed inside the container to be filled.

Further, the floats themselves are attached to the bar. They should be evenly spaced along the entire length of the tube so that after fixing and adjustment is completed, some free space remains around each device.This way, it is possible for each module to perform its own function without disturbing its neighbors.

The cables coming out of the switches are attached to the rod base with clamps. This method makes it possible to mount almost any number of switches, which will ensure complete control over the entire complex, even if it consists of several pumps.

In addition, if the need arises, you can use more than two rods and, accordingly, mount more devices on them. Naturally, this will be necessary only with a fairly large volume of the tank, as well as when control must be carried out for several pumps at once and signals must be sent to several control panels.

Repair and service

The float switch itself is a rather simple and convenient device in design. It functions efficiently and efficiently even in aggressive environments and is not afraid of heavy loads. Subject to the operating rules, which the manufacturer describes in the instructions for the device, even having worked out the entire declared operational life, the device can function successfully for a long time.

It should be noted that if the module is used exclusively in drainage or water supply systems, then it does not even require preventive maintenance, because water is not considered an aggressive medium and has the least negative effect on the device. Regular maintenance is required for modules operating in corrosive environments where the pumped liquids are full of foreign solid particles, such as in drainage or faecal systems.

Plumbing experts recommend flushing the device with a hose at least once every thirty days in order to avoid sticking of the device itself to the pressure pipes or pump walls during daily work. If you rinse the device regularly with a pressure of clean water, then it will retain its performance much longer than the manufacturer claims.

The most common device breakdowns include the following cases:

- Burnout of contacts in an electric cable;

- Violation of the insulating layer;

- Damage to the sealed case;

- Penetration of water into the body.

In all the cases described above, the damaged structural elements will have to be replaced with new ones, since they cannot be repaired. If the electronic filling itself has undergone a malfunction, then it should also be replaced as soon as possible - it will also not be repairable. At the same time, it is not worth buying the first float switch that comes across (even if its price is very attractive), but it is better to apply for a similar model either to the manufacturer or to an authorized dealer. At the same time, a simple pump will bypass much cheaper than working with an unsuitable, but cheap module.

Features of making the right purchase

Before purchasing a float-signaling device, it is necessary to clearly indicate the scope and method of its use, as well as determine the required electrical characteristics, the dimensions of the device itself and the length of the wire. If the float is necessary for drainage or water intake needs, then it will be quite possible to get by with a budgetary model of a light type. It possesses the necessary buoyancy, clearly reacts to the input level in the controlled tank and immediately transmits a signal to other parts of the system involved in the process, if any changes occur. But for drainage and fecal systems, special heavy and expensive modules will be needed (sometimes they are not even equipped with sinkers), because their design assumes close interaction with an aggressive environment.It is worth noting that they should not be purchased for pure water, because their return will be equal to the easy ones, and the price is orders of magnitude higher.

Some nuances of electrical characteristics

The voltage and current of the float unit must clearly correlate with the same parameters of the pumping equipment used. The voltage is usually 220 volts, fluctuations in this indicator are permissible in the range from 5 to 10 percent (in both directions). However, the amperage at the breaker must exceed the limits required for the pump. The instructions for the floats often indicate the active / reactive load. Accordingly, when connecting it to a pump, this position should be taken into account according to the reactive indicator.

The operating temperature of the float devices is quite large - so there is absolutely no need to take care of this. Another thing is the length of the outgoing connection cable - as a standard it has a length of 2 to 10 meters. Devices with a short cable are suitable for household tanks of shallow depth, and long cables are useful for working in water utility tanks or deep wells or wells.

Rating of the best float switches for 2020

Mechanical models

3rd place: Aquatek 1 ″ 0-16-3065

A simple and reliable unit in operation, more designed for work at the household level. In industrial conditions, it is preferable to install the group immediately by means of a rod mount. It has all the necessary characteristics and is easy to install.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Connection type | H1 |

| Manufacturing material | Plastic |

| Working pressure, bars | 6 |

| Working temperature, degrees Celsius | 0 to +50 |

| Price, rubles | 1300 |

- Simple installation;

- High reliability;

- High-quality workmanship material.

- The functionality is not enough for industrial facilities.

2nd place: "NT" QuickStop 1

Another standard model designed for domestic use. According to customer reviews, it has a more durable design and the locking process is much clearer. Even over time, you do not have to replace the adjusting shoulder. Installation and integration into the tank is simple and intuitive.

| Name | Index |

|---|---|

| Manufacturer country | Italy |

| Connection type | H1 |

| Manufacturing material | Plastic |

| Working pressure, bars | 6 |

| Working temperature, degrees Celsius | 0 to +50 |

| Price, rubles | 1800 |

- Durable body;

- Extended service life;

- Doesn't need frequent prophylaxis.

- Quite a high price for a mechanical model.

1st place: "NНT" QuickStop G3 / 4 "

A versatile unit that can be used in tanks of various depths. Its control arm can be extended by adding insertable segments up to 7 meters. Also, the body is specially designed for the passage of water at a high pressure (60 MPa).

| Name | Index |

|---|---|

| Manufacturer country | Italy |

| Connection type | HP ¾ |

| Manufacturing material | Plastic / polycarbonate |

| Working pressure, bars | 15 |

| Working temperature, degrees Celsius | 0 to +50 |

| Price, rubles | 2200 |

- Increased bandwidth;

- Heavy-duty body;

- Modified connection type;

- The length of the controlling shoulder is from 60 cm to 7 meters.

- Requires monthly supervision of the strength of the hitch of the control arm joints.

Electric models

3rd place: UNIPUMP 74528

One of the most popular models, fully justifying its functionality in the category of "price / quality ratio". The set has a good completeness, including a long cable and is perfect for working in running water and in medium aggressive environments.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Load, volt and ampere | 220 and 8 |

| Manufacturing material | Plastic |

| Working temperature, degrees Celsius | Up to 60 |

| Price, rubles | 810 |

- Does not require constant prophylaxis;

- Ease of integration into any tanks;

- Additional cargo included.

- Not very durable case.

2nd place: Tecnoplastic FOX 5 m

This float switch is intended for use in drainage / water supply systems (only for running water). Has a strengthened system of protection of the case according to the European standard IP68. The warranty has been extended from half a year to a year and three months. Officially produced in Russia under an Italian license.

| Name | Index |

|---|---|

| Manufacturer country | Italy |

| Load, volt and ampere | 220 and 8 |

| Manufacturing material | Plastic |

| Cable material | H05 RN-F |

| Maximum immersion, meters | 10 |

| Working temperature, degrees Celsius | Up to 60 |

| Price, rubles | 810 |

- High-quality body material;

- Relatively long wire included (5 meters);

- Extended warranty period.

- Not found (for its class).

1st place: Tecnoplastic TAURUS 10 m

A classic, versatile and very expensive model of a heavy float switch. Adapted to work in any environment. The body is painted in a yellow signal color, which makes it more visible against the background of dark liquids. Designed to operate at ultra-deep depths (up to 20 meters).

| Name | Index |

|---|---|

| Manufacturer country | Italy |

| Load, volt and ampere | 220 and 8 |

| Manufacturing material | Plastic |

| Cable material | Neoprene |

| Maximum immersion, meters | 20 |

| Working temperature, degrees Celsius | Up to 60 |

| Price, rubles | 3700 |

- Versatility;

- Work at great depths;

- Good wire insulation.

- Extremely high price.

Instead of an epilogue

Due to the fact that the described technique is quite simple in design, it is hardly necessary to be afraid of using especially low-quality materials in its composition. It can be purchased both in retail chains and through Internet sites. However, this will be true only in relation to household models. To ensure the efficient operation of sewer systems and in large-capacity tanks, when several sensors are required, it is more profitable to make a purchase via the Internet. Heavy floats-signaling devices for drainage cost 3-5 times more than for running water, so online purchase will significantly save on the difference with the retail price.

new entries

Categories

Useful

Popular articles

-

Top rating of the best and inexpensive scooters up to 50 cubic meters in 2020

Views: 97661 -

Rating of the best materials for noise insulation for an apartment in 2020

Views: 95022 -

Rating of cheap analogues of expensive drugs for flu and colds for 2020

Views: 91751 -

The best men's running shoes in 2020

Views: 87681 -

Top ranking of the best smartwatches 2020 - price-quality

Views: 85091 -

Best Complex Vitamins in 2020

Views: 84801 -

The best dye for gray hair - 2020 top ranking

Views: 82406 -

Rating of the best wood paints for interior use in 2020

Views: 77202 -

Ranking of the best action cameras from China in 2020

Views: 75269 -

Rating of the best spinning reels in 2020

Views: 74827 -

The most effective calcium supplements for adults and children in 2020

Views: 72463 -

Top rating of the best means for male potency in 2020 with a description

Views: 68296