Ranking of the best excavator grabs for 2020

A grab (from the German "greifen" - "to grab") is a device designed for pulling / loading pillowcase (dusty, loose, lumpy) and other piece goods. They can be subdivided into a couple of types: grab buckets for digging up the earth and grab grabs, necessary for unloading / loading operations. The former are often used for digging wells or cleaning wells, while the latter are employed in auxiliary work for the movement of various goods in various industries (from construction to shipping).

Excavators, loaders, as well as cranes can be equipped with grab equipment - grabs are installed on their lifting boom.

Control of such a mechanism is reduced to two simple actions - the capture of the load by the jaws of the apparatus and its direct movement. Depending on the type of control, these mechanisms can be rope or motor (drive).

Rope grabs: their types and principle of operation

They are driven by control cables that are wrapped around the drive drums. In turn, the drums are placed on winches, which are mounted on a lifting mechanism, and the grab itself is suspended from it. Depending on the number of control ropes, the devices can be multi-cable and single-cable. The former can differ in the number of ropes used - 2, 3 and 4 ropes.

The efficiency of the grapple digging on the edges is directly dependent on the speed at which its jaws close and on the speed at which the drum located on the drive rotates. Also, the weight of the machine itself will play an important role, because it must provide full stability on the surface.

IMPORTANT! The most common problem with excavators with such equipment is the increased drum rotation speed, which leads to poor-quality soil grab, because the increased speeds do not allow you to go deeper into the material. Ultra-high speeds will also become a problem for light excavators, as their mass will not provide the downforce needed, for example, when working on compacted soil types.

Single-rope grabs

They can be controlled by means of one rope, which will be responsible for both lifting and closing the jaws.The main advantage of such devices is that more than one winch is not required for work, and the installation of the equipment itself is very simple - you just need to fasten the hooked bracket to the hook. Among other things, single-rope mechanisms are extremely popular when carrying out work that requires frequent replacement of attachments.

The whole cycle of operation of single-rope grabs consists of the following steps:

- Lowering. The lifting winch is used to lower the grab, with the open-jawed grapple lowered onto the surface to be mined. Often, the bucket is not slowly lowered, but simply thrown, which allows deeper entry into the ground. This method allows you to more effectively interact with dense material;

- Capture. The lock mechanism snaps into place, and the winch initiates the start of lifting the load, while the jaws gradually begin to close, gripping the material;

- Climb. After the jaws have closed completely, and the winch at this time continues to work upward, winding the rope. In the process, the bucket breaks off the work surface and rises to a small height;

- Unloading. The bucket is moved by the operator to the desired location and lowered to the surface. This leads to the opening of the lock and the beginning of the bucket lifting, which leads to full opening of the jaws and the release of the load.

As you can see from the above cycle, operations with a single-rope grab are more tied to the use of gravity (opening the lock when lowering, throwing the bucket for a better grip, etc.). All this lowers the quality of effective work. Therefore, in this system, additional devices can be used, for example, an unloading cable (forcibly blocks the jaws, regardless of what height the bucket itself is at) or stabilizing cables (prevent excessive swinging of the gripper during manipulation).

Two-rope grabs

They are distinguished from those described above by the presence of two drum drives operating independently of each other. One is responsible for vertical movement, and the other is responsible for manipulating the jaws. In general, such a system significantly reduces cable wear, increasing the overall reliability of the entire mechanism.

The cycle of work on two ropes is a bit incomparable with a single-rope one:

- Lowering. At this moment, the jaws are in a fully open state, and the descent is carried out more slowly;

- Capture. When in contact with the surface to be treated, the second cable begins to work, its efforts ensure better closure of the jaws and high-quality material intake;

- Climb. After the jaws are fully closed, both winches begin to work - one works to move, and the second supports the closed bucket. The main problem at this stage is to ensure synchronous operation of both ropes, which is not always possible. Therefore, most modern grabs are equipped with automatic synchronization devices;

- Unloading. The opening of the bucket hanging at the height is carried out by loosening the cable responsible for the manipulation of the jaws.

This system of two-rope grabs is the most popular and efficient, and when using special synchronizers it is the most preferable in terms of price / quality ratio.

3 and 4 rope grabs

By and large, their principle of operation is not much different from the two-cable system - it's all about enhanced support for the operation of the mechanism at a certain stage. In a three-rope system, one rope is responsible for lifting / lowering, and the other two are responsible for opening / closing the jaws. In a four-rope system, one cable is separately responsible for the descent, the other for the ascent, the third for opening the jaws, and the fourth for closing them. Thus, an increase in the number of cables in the system only leads to an improvement in its reliability.

Motor grabs (drive)

In such systems, the jaws are controlled using a separate, separate drive that transfers power from the diesel / electric engine to the working elements.

The very same engine, transmitting the force, can be included in the grab structure itself or placed outside its limits with placement, for example, on the loading and lifting mechanism. The latter option means additional supply of separate cables to the grab device.

By the type of motor, these grippers are divided into:

- Electromagnetic - they temporarily create a magnetic field under the action of an electric current, which forces the jaws to close. When the formation of the magnetic field stops (by turning off the electric current), the jaws open. This grip is convenient to use when loading / unloading various types of metal objects, because even the smallest metal shavings will be collected when the magnetic field is working, when the jaws are closed;

- Electromechanical - the working force, which makes the jaws close / open, is transmitted to them using either a gear, or belt, or gear, or screw, or other transmission mechanism. Such grabs are the simplest and most reliable in their class, thanks to the articulated jaw system, which is powered by an electric motor with a polypast;

- Hydraulic - equipped with a system of supply hoses (hoses) and special hydraulic cylinders. By pumping liquid into the cylinder capacity, the gripper is lowered / lifted, as well as the jaws are opened and closed;

- Pneumatic - they have the same principle of operation as hydraulic, except that the pumped liquid is replaced by air, which is supplied using a special compressor.

Buckets and Pliers: Differences in Grip by Jaw Type

The shapes of the jaws determine what type of material the gripper is capable of handling:

- Bucket grabs are used for digging, used for mining. They often have to work with dense soil, therefore, the bucket edge can be additionally equipped with sharpened teeth;

- Clamp grabs are designed for loading round timber, various pipes (both metal and plastic), working with scrap metal;

- Fork grabs are usually used in the agro-industrial sector - they are convenient for loading hay, silage, and other loose or fibrous materials.

Various loose / small lump goods (especially those that may leak out) are loaded using closed (or semi-closed) bucket grabs. It is their tight closing of the blades that does not allow the load to be lost.

Also, the grippers can differ in the trajectory of use. Diggers are adapted for a pronounced sharp angle of penetration into the working surface, while loading is enough to work at a right angle.

Among other things, some grapples can be multifunctional and made to meet specific needs. As a rule, such models are equipped with a rotary rotator of the grab, which allows them to be used for both digging and loading.

The main characteristics affecting the cost of the grab

The cost of the described attachments for an excavator consists of many parameters:

- Capture capacity in cubic meters;

- Maximum lifting capacity;

- Dimensions in open and closed state;

- Weight of the device without load;

- Type of drive used;

- Number of jaws at the grip;

- The type of cargo for which the grab can be used;

- Possible material density (for diggers);

- Drive power (for those equipped with a motor);

- Number of ropes (for rope).

Thus, it is possible to give specific prices only by choosing specific parameters, and their choice will depend on the area in which the equipment will need to be used.

Ranking of the best excavator grabs for 2020

Forestry hydraulic grab ARBOR 4-0

Currently, this grip is the flagship among the models from the German company "Wimmer International". Specially designed for loading / unloading round timber. The body and blades are made of WHD-450 high wear resistance steel. Freely copes with the movement of logs with a diameter of 220 mm, while not causing them serious damage. After turning off the engine, the blades will still hold the load for half an hour. The purpose of the grab can be easily changed by changing the blades.

| Name | Index |

|---|---|

| Manufacturer country | Germany |

| Curb weight in kilograms | 1490 |

| Maximum blade opening in millimeters | 1720 |

| The minimum diameter of round timber in millimeters | 220 |

| Working fluid flow in the clamping hydraulic circuit, liters per minute | 70-120 |

| Pressure in the hydraulic circuit in bars | 350 |

| Warranty, years | 1 |

| Price, rubles | 420000 |

- Convenient blade change;

- Wear-resistant housing;

- Retention of cargo during emergency shutdown of systems.

- There may be problems finding consumables.

Anvil Attachments Magnetic Metal Load Grab

A round electromagnet is installed in the design of the device, which works much more efficiently than the classical one, because it uses the "finite element method". Due to the use of a special alloy (alloy steel A-514) in the blades, it was possible to increase their strength, while reducing their weight by 35%. The hinge pins have undergone additional processing, which will significantly increase their service life. The blades themselves can be supplied in both closed and semi-closed configurations.

| Name | Index |

|---|---|

| Manufacturer country | USA |

| Curb weight in kilograms | 1700 |

| Volume of supplied buckets in cubic meters | 0,6-1,5 |

| Cylinder pressure in Megapascals | 34.5 |

| Warranty, years | 1 |

| Price, rubles | 850000 |

- Huge variety of equipment;

- The body is made of alloy steel;

- Relatively low dead weight.

- High price, despite the fact that absolutely all attachments may be needed only by a very narrow circle of buyers.

Sennebogen SMG Series Bucket Grab

Multifunctional grapple capable of working both with metal and adapted for digging the ground. The cutting edges can be equipped with sharpened carbide tipped teeth. The construction uses materials that do not harm the environment. It can be used as well as an earth-moving tool. A version with replaceable pads for working under water (at shallow depth) is available.

| Name | Index |

|---|---|

| Manufacturer country | Germany |

| Carrying capacity in kilograms | Up to 15,000 |

| Number of blades | 2 |

| Bucket volume in liters | 2000 |

| Maximum coverage area in meters | 2 |

| Cylinder pressure in Megapascals | 38 |

| Warranty, years | 2 |

| Price, rubles | 650000 |

- Extended service life;

- Application of ecological materials in construction;

- Multifunctionality.

- Requires periodic prophylaxis.

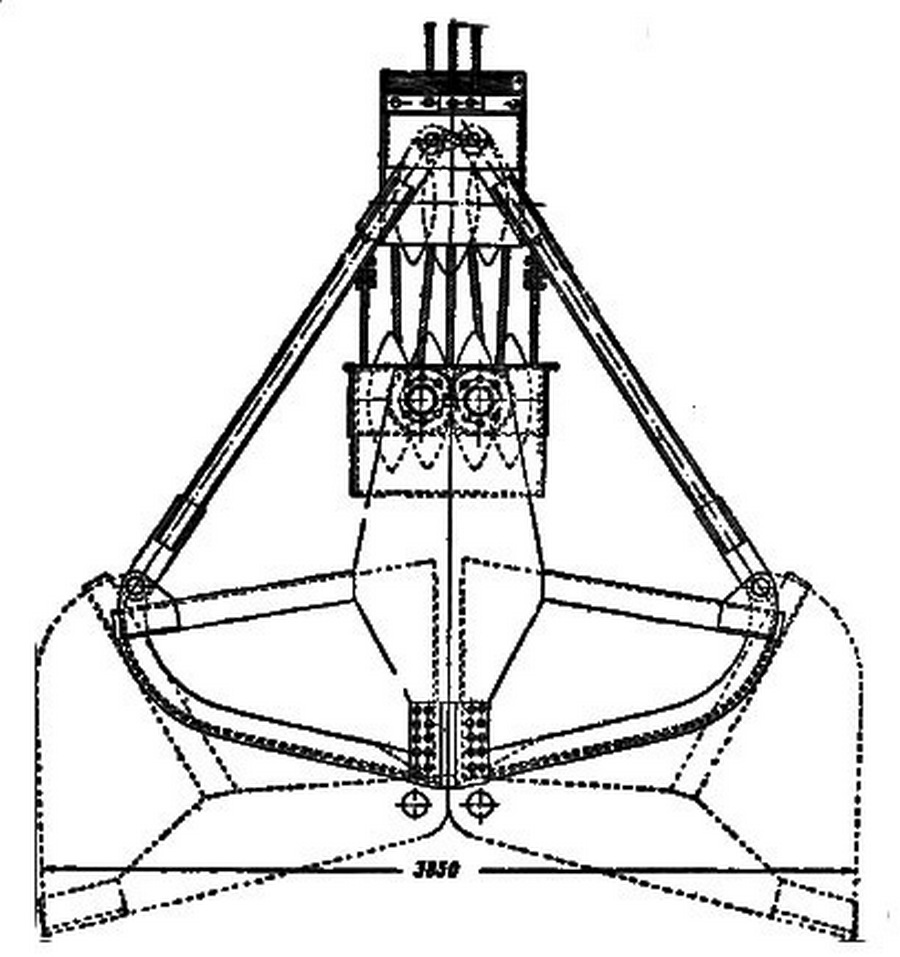

Rope grab "Professional"

This Russian-made equipment is designed to work with various bulk materials of different density. The equipment is perfect for loading and unloading, and can be used in seaports and quarries for mining.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Carrying capacity in kilograms | Up to 10,000 |

| Number of blades | 2 |

| Bucket volume in liters | 1000 |

| Maximum coverage area in meters | 1.5 |

| Cylinder pressure in Megapascals | 33 |

| Warranty, years | 0.5 |

| Price, rubles | 350000 |

- Budgetary price;

- No problems with accessories (representative offices in 38 largest cities of the Russian Federation);

- Good technical support.

- Narrow scope of application;

- Impossibility of modernization.

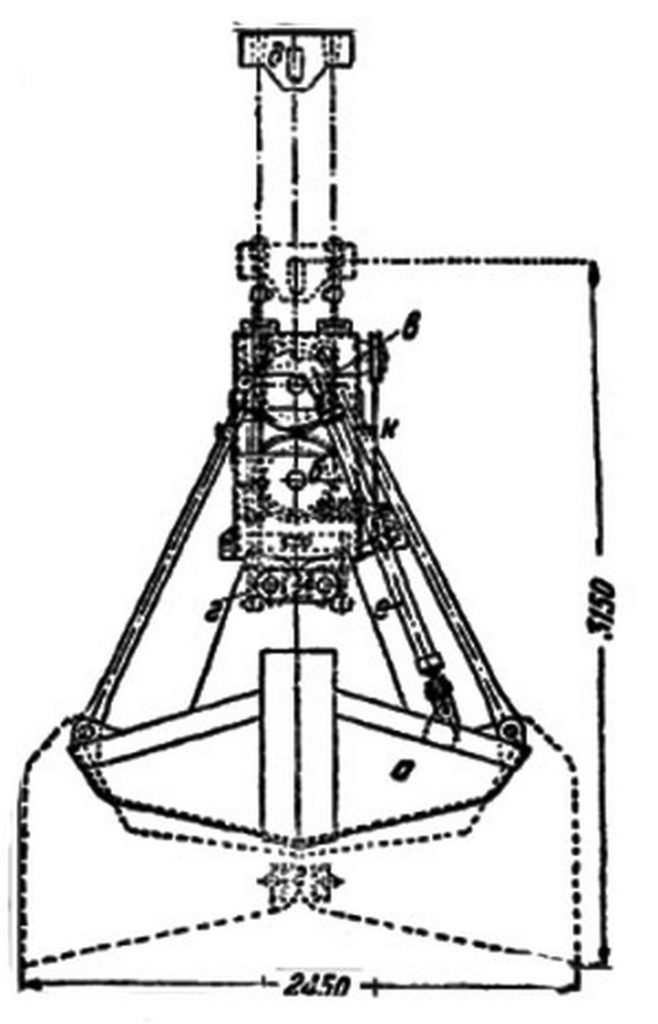

4-rope grab VVMZ model VG2-2-S3-4k-O, 5

Another model of the reinforced gripper from the Russian Volgo-Vyatka Mechanical Plant. Designed for the transportation of bulk substances - clinker, limestone, wet sand, metallurgical slag.The use of four ropes in the system significantly increases the service life, while the force produced during the grip is increased fourfold.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Carrying capacity in kilograms | Before 2000 |

| Number of blades | 2 |

| Bucket volume in liters | 500 |

| Maximum coverage area in meters | 0.5 |

| Unladen weight in tons | 0.5 |

| Warranty, years | 0.5 |

| Price, rubles | 250000 |

- Increased wear resistance;

- Increased grip force;

- Great variety of materials for handling.

When transferring ropes, significant delays in work are possible.

Clamshell grab for excavator-material handler CAT G315B WH

The model is extremely limited in its functionality, which cannot be said for its price (quite high). In this case, the manufacturer's brand, Caterpillar, plays an important role, having proved itself to be the best in this market segment over the last century. The specified model is intended exclusively for work with low-density materials (plastic waste, food waste, etc.)

| Name | Index |

|---|---|

| Carrying capacity in kilograms | 1450 |

| Service volume in liters | 800 |

| Force applied in kilonewtons | 50 |

| Circuit pressure in bar | 350 |

| Liquid consumption in liters per minute | 90 |

| Required mass of equipment in tons | 15-22 |

| Guarantee | 1 |

| Price, rubles | 900000 |

- The manufacturer's brand guarantees the reliability of the structure;

- Extended scope of the work item;

- Optimum flow rate in the circuit.

- Low functionality.

Instead of an epilogue

The conducted market analysis shows that this segment is quite saturated with various models and allows you to make a reasonable choice. If you dwell on foreign brands, then the secondary market is more filled with them. Russian brands occupy an average position in the primary market, but only due to their reduced price. In any case, the choice between used and new equipment should be made based on the current tasks and the expected duration of the device. It is worth noting that it is absolutely impossible to navigate the prices by monitoring Internet sites for new models - it is possible to find out the price for new copies only by requesting it directly from a dealer or manufacturer. In turn, the search for the required model in the secondary market is extremely limited, as a rule, it is not possible there to assemble the clamshell gripper completely "for yourself" and you have to look for the required complete set in a ready-made version for a long time.

new entries

Categories

Useful

Popular articles

-

Top rating of the best and inexpensive scooters up to 50 cubic meters in 2020

Views: 97661 -

Rating of the best materials for noise insulation for an apartment in 2020

Views: 95022 -

Rating of cheap analogues of expensive drugs for flu and colds for 2020

Views: 91751 -

The best men's running shoes in 2020

Views: 87681 -

Top ranking of the best smartwatches 2020 - price-quality

Views: 85091 -

Best Complex Vitamins in 2020

Views: 84801 -

The best dye for gray hair - 2020 top ranking

Views: 82406 -

Rating of the best wood paints for interior use in 2020

Views: 77202 -

Ranking of the best action cameras from China in 2020

Views: 75269 -

Rating of the best spinning reels in 2020

Views: 74827 -

The most effective calcium supplements for adults and children in 2020

Views: 72462 -

Top rating of the best means for male potency in 2020 with a description

Views: 68296